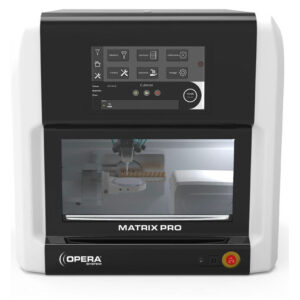

MATRIX

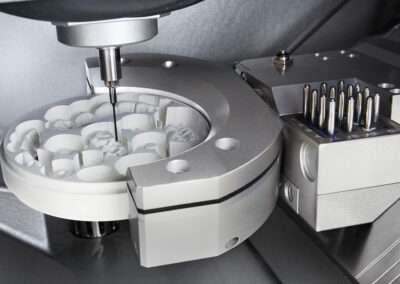

Machining of CAD-CAM blanks and blocks

Matrix offers high flexibility and production capacity to meet capacity to meet all requirements.

- High precision

- Machining of special metals

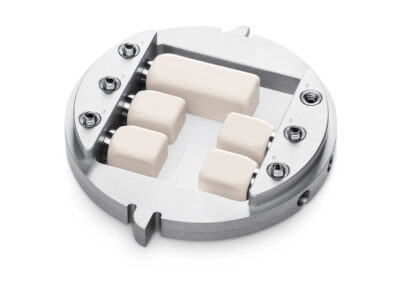

- Blanks up to 40 mm for complete prostheses

- Stop-and-go milling (schunk attachment)

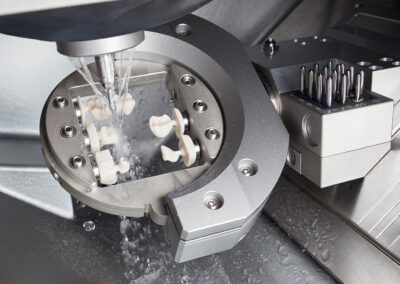

A combination of power and precision, Matrix offers you milling of the highest quality. Specialised in metal machining thanks to the

power of its water-cooled spindle, Matrix can mill any type of material. Its Schunk shank will allow ‘stop and go’ machining without

loss of precision.

| Fields of application | Wet and dry |

| Dimensions | 650 x 700 x 830 mm |

| Weight | ±180 kg |

| File Format | STL |

| No. of axes | 5 |

| Positioning Range | A rotary axis of 360 degrees B rotary axis (fifth axis) of ± 40 degrees |

| Blank thickness | 10 to 40 mm – Ø 98 mm |

| Automatic Tool Changer | 22 tools |

| Machinable materials | Zirconia, Wax, PMMA, CoCr, Peek, Acetal, Titane, Premilled, Nanoceramic, Feldspath, Lithium disilicate, Composite resin, etc |

| Air Consumption | ± 100 l/min to 7 bars |

| Repetition accuracy | ± 0.0001 mm |

| Rotation Speed | Jager chuck spindle rotating up to 60000 RPM |

| Collet chuck | 6 mm |

| Power supplu | 230V ac 3500w |

| Maximum power | 3200 watts |

| Support | 6 blocs |