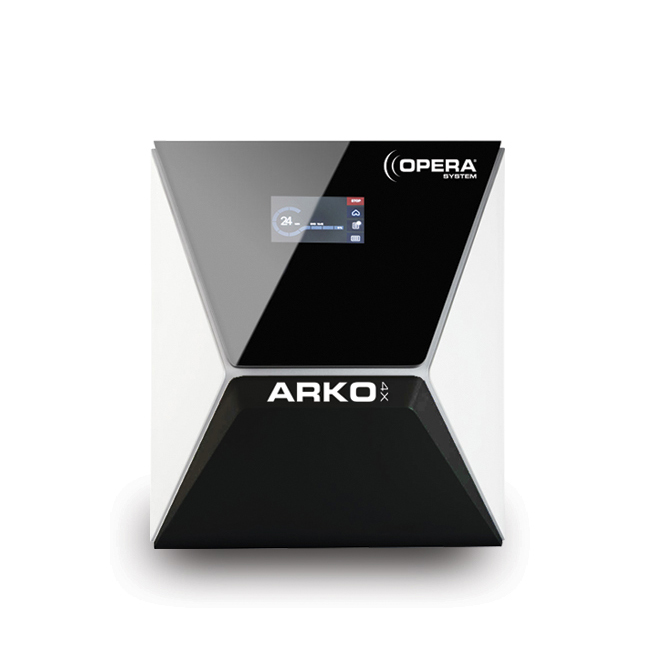

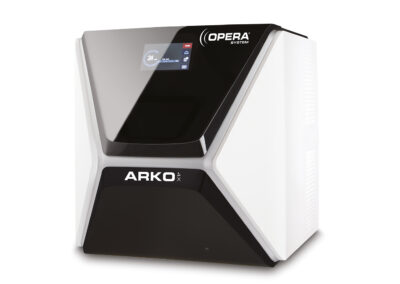

ARKO

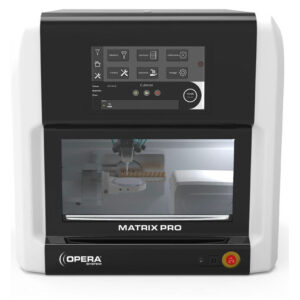

Fast and precise block machining

- Integrated compressor

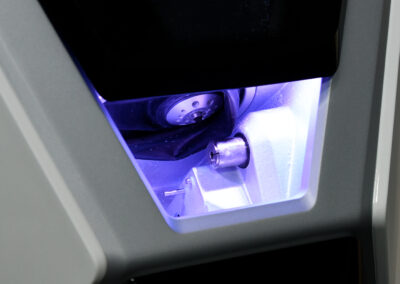

- Ultra-HD milling and grinding

- Easy and intuitive operation: Automatic block assembly and clamping in 1 click

- Quiet and comfortable solution: Sealing and soundproofing

- Cast aluminum frame for better seating and stability

Restorations in less than 10 minutes!

Highest precision

- Milling and grinding in ultra HD

- Proven industrial quality

- 3 microns repetition accuracy

Fastest production

- Restorations in under 10 minutes

- 2-second block insertion

- 100,000 RPM electrical high frequency spindle

Extremely economical

- Clear water

- no additives necessary

- Automatic changer for 6 tools

- Self-opening working chamber door and drawer

- Easy to learn, easy to operate

Complete independence

- 38 block materials from 20 manufacturers – and growing

- >800 prefab titanium abutment blanks from 11 manufacturers

- Validated with all established scanners and design software

- Fully integrated workflow with DWOS chairside (Dental Wings) and exocad ChairsideCAD*

- Integrated PC with touch screen and Wi-Fi – no laptop or tablet necessary

- Built-in compressed air – no compressor needed

* Material and indication availability may vary by CAD provider. Full range of indications and materials available in STL workflow.

Milling software – DentalCAM

- High-performance software package with open STL import for all common CAD programs

- Optimized CAM strategies for the fastest possible machining

| Fields of application | Wet grinding |

| Dimensions | 471 x 522 x 507 mm |

| Weight | ~66 Kg |

| File Format | STL |

| No. of axes | 4 |

| Automatic Tool Changer | 6 outils |

| Machinable materials | Premilled – Nanoceramic – Feldspath – Zirconia – PMMA – Lithium Disilicate – Lithium silicate – castable resin |

| Repetition accuracy | ± 3 microns |

| Rotation Speed | jusqu’à 100 000 tours / minute |

| Pure water | No additives necessary |

| Integrated service webcam | ✔︎ |

| Compressor inside | ✔︎ |

| Touch screen | ✔︎ |

| Integrated PC | ✔︎ |