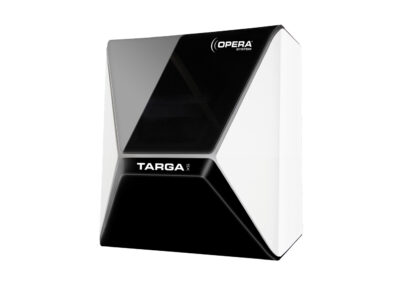

TARGA

Machining of CAD-CAM blanks and blocks

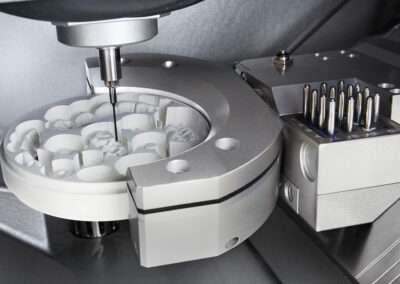

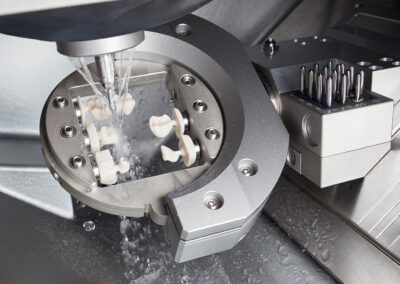

With the new high-end TARGA dental lab machine, Opera System propose a highly automated milling and grinding machine with a tenfold blank changer for both wet and dry machining, bringing revolutionary approaches to the lab.

It combines utmost precision with maximum stability regardless of material – all with a minimal footprint.

- 5 axis dry and wet machining

- Automatic changer of 10 blanks

- Machining of blanks with a thickness of 10 to 40 mm

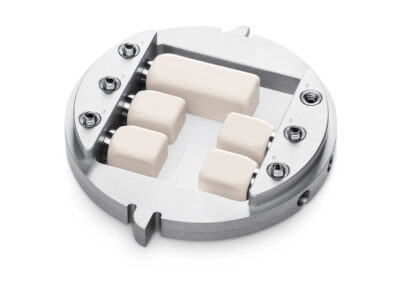

- Machining of blocks (supports for blocks) : 60 blocks

- Machining of premilled titanium abutments

- Automatic management of 16 tools

- 2 integrated webcams

- Rotation axis A of 360° and rotation axis B (5th axis) ± 35°s

Maximum precision

- Restorations in ultra HD

- Premium spindle with 4-fold hybrid ceramic ball bearings for maximum running smoothness

- 3 microns repetition accuracy

Powerful and robust

- Mills and grinds the toughest materials on the market including all Ti and CoCr

- 800 watts of power and 80,000 RPM

- Heavy industrial quality

Absolute independence

- Sheer unlimited material accessibility in 98 mm disc format, 30 block materials, and >800 titanium and CoCr prefab abutment blanks

- Covers the broadest range of indications, due to ±35° rotation angle in the 5th axis, and up to 40 mm blanks

Unmatched reliability

- 100% engineered and manufactured in Germany

- Comprehensive sensor technology to monitor all vital system functions

- Webcam in working chamber for remote monitoring

Highly economical

- One of the fastest machines on the market

- Revolutionary material loading with DirectDiscTechnology (patent pending)

- Automatic changer holds up to 10 discs, 60 blocks, or 60 prefab abutment blanks

- DirectCleanTechnology enables wet and dry on the fly: ionizer, self-cleaning and built-in dryer (patent pending)

Milling software – DentalCAM

- High-performance software package with open STL import for all common CAD programs

- Optimized CAM strategies for the fastest possible machining

| Fields of application | Wet and dry |

| Dimensions | 580 x 600 x 700 mm |

| Weight | ±149 kg |

| File Format | STL |

| No. of axes | 5 |

| Automatic charger | 10 blanks – support 60 blocks |

| Blank thickness | 10 to 40 mm – Ø 98 mm |

| Automatic Tool Changer | 16 tools |

| Machinable materials | Zirconia, Wax, PMMA, CoCr, Peek, Acetal, Titane, Premilled, Nanoceramic, Feldspath, Lithium disilicate, Composite resin, etc |

| Positioning Range | A rotary axis of 360 degrees B rotary axis (fifth axis) of ± 35 degrees |

| Air Consumption | Ionizer deactivated: approx. 50 l/min at 6 bar, 65 l/min at 8 bar Ionizer activated : approx. 100 l/min at 6 bar, 110 l/min at 8 bar |

| Repetition accuracy | ± 3 microns |

| Rotation Speed | up to max 80,000 RPM |

| Integrated service webcam | ✔︎ |

| Built-in ionizer | ✔︎ |

| Tool-free blank clamping system | ✔︎ |