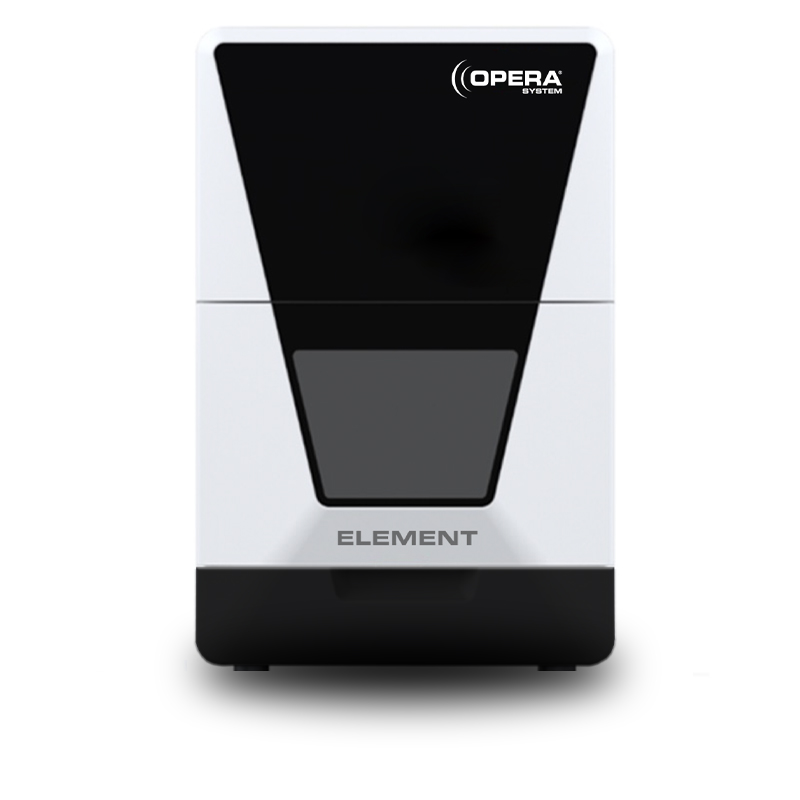

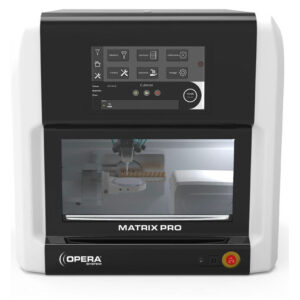

ELEMENT

DRY MILLING 5 AXIS

Optimize your digital workflow, enjoy maximum freedom and achieve optimal results.

Thanks to the absence of compressed air, you have complete freedom to choose the location of the machine and you also benefit from extremely low operating costs. Element allows you to easily start the digital production of your dental restorations and integrates seamlessly into your workflows. With the included CAM software, you can get started right away!

- Disc thickness up to 40 mm

- 5 axis dry milling

- Optimal use of blanks

- Automatic tool changer 17 tools

- Option: 6 blocks holder

- Color coded tools

| Fields of application | Dry machining |

| Dimensions | 472 x 484 x 734 mm chiuso – 472 x 567 x 734 mm aperta |

| Weight | ± 43 kg |

| File Format | STL |

| No. of axes | 5 |

|

Blank thickness |

10 a 40 mm Ø 98,5 mm |

| Automatic Tool Changer | 7 tools |

| Machinable materials | Zirconia, Wax, PMMA, Peek, Acetal, nanoceramic |

| Positioning Range |

A rotary axis of 360 degrees – B rotary axis (fifth axis) of ± 35 degrees |

|

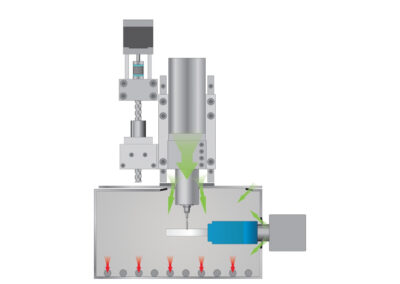

No compressed air |

AIRTOOL patent |

| Repetition accuracy | ± 5 microns |

| Rotation Speed | up to max 60,000 RPM |